Keeping Hearing Aids Dry with the Redux System: A Game Changer for Hearing Aid Users

Hearing aids are essential devices for millions of people worldwide, providing a significant improvement in the quality of life for those with hearing loss. However, these sophisticated devices are also delicate and prone to issues caused by moisture. Whether it’s from sweat, humidity, or accidental water exposure, moisture can lead to malfunctions, reduce sound quality, and significantly shorten the lifespan of hearing aids. At Hears to U, we are committed to providing the best hearing aid care for your needs. Today we are thrilled to introduce our latest solution: the Redux Moisture System.

Understanding the Impact of Moisture on Hearing Aids

Hearing aids are intricate pieces of technology with many tiny components working together to amplify sound. When moisture enters these devices, it can cause a variety of problems:

- Corrosion: Moisture can corrode the metal components inside hearing aids, leading to permanent damage.

- Short Circuits: Water and electronics don’t mix well. Moisture can cause short circuits that may render the device unusable.

- Degraded Performance: Even small amounts of moisture can affect the sound quality, making the hearing aid less effective.

- Battery Issues: Moisture can significantly reduce battery life, causing inconvenience and additional expenses for the user.

Introducing the Redux Moisture System

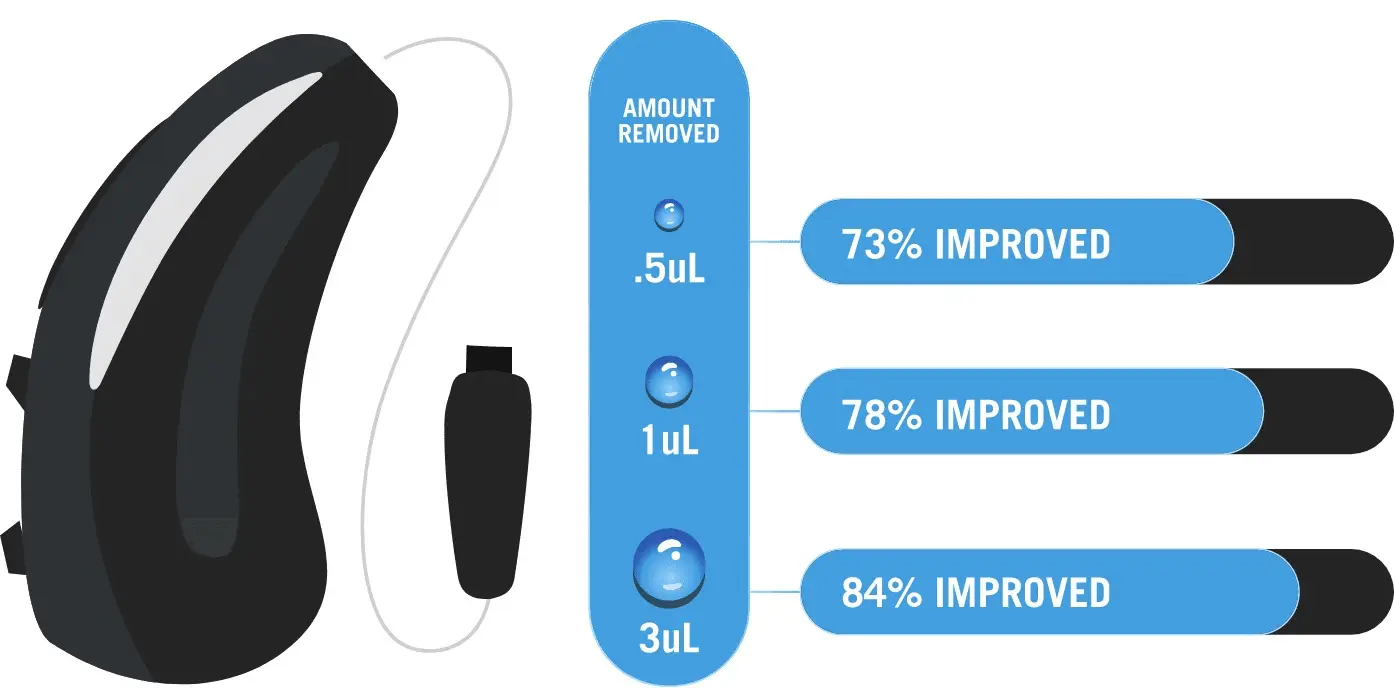

To address these hearing aid care issues, we have incorporated the Redux Moisture System into our service offerings. The Redux system uses advanced technology to remove moisture from hearing aids quickly and safely. Here’s how it works:

Vacuum Drying Process: The Redux system employs a vacuum drying process that gently yet effectively removes all moisture from the tiny crevices and delicate components of hearing aids. This process is thorough, ensuring that every part of the hearing aid is completely dry.

Quick and Efficient: The entire drying process takes only a few minutes, allowing users to have their hearing aids back in no time.

Safe for All Devices: Whether you have over-the-ear or in-the-ear hearing aids, the Redux system is designed to be safe and effective for all types.

Advanced Vacuum Technology in the Redux Moisture System: Ensuring Optimal Hearing Aid Performance

High-efficiency vacuum pumps are pivotal in numerous scientific and industrial applications due to their ability to create low-pressure environments essential for various processes, including drying, distillation, and material handling. The Redux system leverages this advanced technology to provide effective moisture removal from hearing aids.

Research and Applications of High-Efficiency Vacuum Pumps

High-efficiency vacuum pumps are designed to evacuate air from a sealed chamber. Therefore creating a vacuum that significantly reduces the atmospheric pressure inside. This pressure reduction lowers the boiling point of water, allowing for the evaporation of moisture at lower temperatures. This technology is rooted in fundamental thermodynamics. Specifically the relationship between pressure and boiling point as described by the Clausius-Clapeyron equation.

Thermodynamic Principles

The Clausius-Clapeyron equation describes how the vapor pressure of a liquid varies with temperature. In a vacuum environment, the reduction in atmospheric pressure allows water to evaporate at much lower temperatures. For instance, at standard atmospheric pressure (101.3 kPa), water boils at 100°C (212°F). However, under a vacuum, the boiling point can drop to as low as 20-30°C (68-86°F). This makes vacuum drying an efficient and gentle method for removing moisture from sensitive materials without subjecting them to high temperatures that could cause damage.

Efficiency and Performance

Research has shown that these pumps can reach pressures as low as 0.1 Pa (Pascal), which is critical for processes requiring high levels of precision and control. For instance, a study published in the Journal of Vacuum Science & Technology highlighted the efficiency of rotary vane and diaphragm pumps in achieving stable and reliable low-pressure environments, essential for applications like freeze drying and semiconductor manufacturing.

Advanced Materials and Design

Modern vacuum pumps incorporate advanced materials and design features to enhance their performance and durability. For example, the use of corrosion-resistant materials like stainless steel and specialized coatings helps extend the pump’s lifespan and maintain its efficiency over prolonged use. Innovations in pump design, such as oil-free mechanisms and magnetic levitation, further improve the efficiency and cleanliness of the vacuum environment, making them ideal for sensitive applications like drying hearing aids.

Application in the Redux System

The Redux system’s high-efficiency vacuum pump is integral to its ability to provide thorough moisture removal from hearing aids. By creating a low-pressure environment within the sealed vacuum chamber, the pump enables the rapid evaporation of moisture at low temperatures. This process is further supported by a gentle heating element that slightly warms the air within the chamber, ensuring efficient evaporation without overheating the delicate electronics of the hearing aids.

Throughout the drying process, advanced moisture detection sensors monitor the humidity levels within the chamber. These sensors ensure that all moisture has been effectively removed before the process is deemed complete, providing users with dry, fully functional hearing aids.

The Vacuum Drying Process

- Placement of Hearing Aids: The hearing aids are carefully placed inside the vacuum chamber. They are positioned to ensure maximum exposure to the reduced-pressure environment.

- Sealing the Chamber: The chamber is then sealed to create an airtight environment. This is crucial for maintaining the low-pressure conditions necessary for effective drying.

- Evacuation of Air: The vacuum pump is activated, rapidly evacuating air from the chamber. This creates a low-pressure environment, reducing the atmospheric pressure around the hearing aids.

- Lowering the Boiling Point of Water: At lower pressures, the boiling point of water decreases significantly. This means moisture within the hearing aids can evaporate at much lower temperatures, preventing heat damage to the delicate electronics.

- Evaporation of Moisture: As the pressure drops, the moisture trapped in the hearing aids begins to evaporate. The gentle heating element helps maintain a slightly elevated temperature, ensuring efficient evaporation without overheating the devices.

- Continuous Monitoring: The system’s sensors continuously monitor the humidity levels within the chamber. This ensures that the drying process continues until all moisture has been effectively removed.

- Completion of Process: Once the sensors detect that the moisture level has reached the desired low threshold, the vacuum pump is deactivated, and the chamber is gradually brought back to normal atmospheric pressure. The hearing aids are then removed, thoroughly dried and ready for use.

Advantages of Vacuum Drying with Redux

- Efficiency: The vacuum drying process is much faster than traditional air drying or desiccant-based methods, typically taking only a few minutes.

- Safety: Vacuum drying lowers the boiling point of water, ensuring that moisture is removed at temperatures safe for the delicate components of hearing aids.

- Thoroughness: The vacuum environment draws moisture out from even the tiniest crevices and hard-to-reach areas within the hearing aids.

- Consistency: The advanced sensors and controlled environment ensure that the drying process is consistent and reliable every time.

Real-Life Success: Paul’s Experience

To illustrate the effectiveness of the Redux Moisture System, let’s consider the case of one of our patients, Paul. Paul had been experiencing issues with his hearing aids for several months. Despite being relatively new, his hearing aids were producing weak sound, and the batteries were only lasting three days. Frustrated with the reduced performance and frequent battery changes, Paul sought our help.

After a thorough examination, we determined that moisture was the likely culprit behind Paul’s hearing aid problems. Although his devices were out of warranty, we suggested putting them through the Redux drying process. Paul agreed, hoping to restore his hearing aids to their optimal condition.

The results were remarkable. After the Redux treatment, Paul’s hearing aids were noticeably clearer and louder. The sound quality was restored, and the battery life also improved significantly. Paul reported that his hearing aid batteries now lasted much longer, eliminating the need for constant replacements. This simple yet effective treatment saved Paul hundreds of dollars, as he no longer needed to consider purchasing new hearing aids.

At Hears to U, Hearing & Hearables we are proud to offer this innovative hearing aid care service to our patients. Whether you’re experiencing issues with your hearing aids or simply want to ensure they stay in top condition, the Redux Moisture System is an excellent choice. Don’t let moisture compromise your hearing experience—take advantage of our Redux services and enjoy clearer, louder sound with longer-lasting batteries.

Contact us today to learn more and schedule your Redux drying session or to buy your own home dryer!

Reference:

Journal of Vacuum Science & Technology